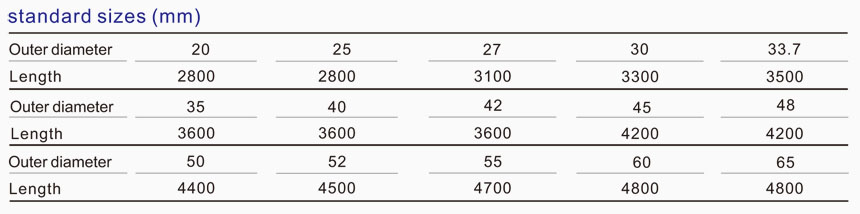

The tubes of the above sizes , we have available stocks. We can also custom cut shorter lengths to your specifications. Other sizes available on request.

How To Use Ceramic Rollers Properly

How to use the roller affects not only the service life of the roller but also smooth work of the kiln. Generally,we select the type of roller depending on the maximum firing temperature and load of the roller,Meanwhile,the rotate speed,span of roller and atmosphere in the kiln are also important factors for us to consider,as well as the factors of the gas,molten materials and thermal shock. Considering the factors mentioned above,our suggestions are the following:

Before using the roller,apply protective coating on the surface evenly.

Place the roller beside or on the kiln for drying. Only after the roller has been dried can it be put into kiln.

Inserting coated roller to kiln should be completed in a short time,in order to avoid the roller to be heated too long in nonrotating state .

Inserting ceramic fibre to both poles at depth 50-60mm.

Keep the temperature in the kiln at a stable level.Change the new roller whenever any roller broken.

When the kiln is warmed up to 300-400℃,Please insert the rollers and increase temperature steadily.

Whenever glaze droplets or alike deposits appear,the roller should be pulled out for cleaning and then applied with new protective coating.

While the roller is pulled out from high temperature kiln,its bending should be avoided.Place it to a stand matted with thermal insulating material, rotate it continuously until it cools down to below 600℃,or cover it with thermal insulating blanket.

Contact between hot roller and cold metal must be avoided.

Don’t use hard tool to knock at roller while cleaning.

Keep the exhausting fan on and roller rotating after shutting down of kiln,turn off the other fans and prevent cold air coming.after 24 hours,increase the fan speed and take out the roller when the temperature in the kiln is 500℃ or below.

For the kiln using coal gas,be sure to turn down exhausting fans in time after turning off coal gas and combustion air The operation of the exchange heat fans depends on the pressure in the klin in order to prevent leakage of the cold air and cool the kiln stably Prevent the cold air coming into the kiln when it is cooling, special for the kiln used the heavy oil.Adjust the fan speed to balance the pressure in the kiln in a stable level,and slow air current to cool the kiln in a stably.

Avoid using the roller in the alkali atmosphere and the corrosion of alkali materials in order to prolong the service time of roller.